Textured Soya Protein/Vegetarian Soya Meat/Soya Nugget Food Process Line takes Defatted soybean meal, pea protein, peanut meal etc as main raw materials. After mixing, extruding, cutting and drying, the meal becomes layer fiber texture, with meat chewy taste, these products are called TVP, TSP, Soya Chunks, Soya Protein, Soya Protein Crumbs etc.

These finished products have high protein; look and taste like meat; easy to absorbing oil, water and flavor; without cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deep frozen food production, and all kinds of vegetarian snacks and food.

1.Market Overview:Soya chunks emerged in developed countries such as Europe and the United States in the 1960s. It can replace high-fat, high-calorie meat foods, also known as "simulated meat". It is a fibrous plant protein with a texture similar to muscle fibers formed by special processing of plant-based protein. Soybean tissue protein began to appear in my country in the 1990s. After years of development, the plant protein industry has begun to take effect and has developed a variety of products and applications.

1.Market Overview:Soya chunks emerged in developed countries such as Europe and the United States in the 1960s. It can replace high-fat, high-calorie meat foods, also known as "simulated meat". It is a fibrous plant protein with a texture similar to muscle fibers formed by special processing of plant-based protein. Soybean tissue protein began to appear in my country in the 1990s. After years of development, the plant protein industry has begun to take effect and has developed a variety of products and applications.

There are two major types of plant protein meat: dry tvp production line and high moisture extrusion meat analogue machines supplier. The main production raw materials are plant protein raw materials, such as soy protein, wheat protein (gluten), peanut protein, etc., which are broken and reorganized under high temperature and high pressure in the extruder to form a fibrous state.

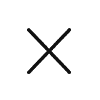

2. Product Description:The plant-based meat production line uses fully automatic equipment and carefully formulated process formulas.

(1)Dry TVP production line: Using soybean, pea and other plant-based proteins as the main raw materials, under the high temperature and high pressure of the extruder, the tissue structure is broken and reorganized to form a good fiber feel and toughness, so that the food has the texture and taste of animal meat. The moisture content of the texturized meat is low and it is easy to store and transport.

(2)Wet TVP production system: Using the international new extrusion cooling process, using soybean, pea and other plant-based proteins as the main raw materials, after extrusion and maturation, a special cooling sleeve equipment is used to plastically cool the plant protein. The product texture can imitate different structures such as chicken and beef, which is an ideal substitute for meat products. HMMA has a high moisture content and does not need to be covered with water again.

3.Production Line Advantages:

(1)Different production lines can be customized according to customer requirements so that customers can better produce different products.

(2)Adopting automatic control system, high energy utilization efficiency, effectively reducing unnecessary energy loss.

(3)Almost zero waste discharge in the production process, in line with the concept of green development of modern industry.

(4)Every component of the equipment will be strictly tested to ensure that it meets or even exceeds national standards.

The company covers a total area of 100 acres, serves more than 1,100 customer factories around the world, sells products to 118 countries and regions, and has a team with more than 30 years of industry experience. The company has won many honorary titles such as "3A-level contract-abiding and trustworthy enterprise" and "high-tech enterprise".

The company has many product R&D personnel and a complete and independent "Food Extrusion Technology R&D Center", which can provide food process research, formula development and application for customers. The company focuses on the R&D and stable production of new products. It conducts many product R&D and new product development with customers every year. The company has reached cooperation with many universities and research institutes to work together for the development of new products.

The company has a complete and perfect after-sales team:

After the project is completed, the after-sales team will follow up with customers from time to time, provide professional analysis, timely feedback, and provide 7*24 hours online consulting services to answer questions encountered by customers during use.

The machine and parts support warranty within one year, and equipment parts enjoy lifetime discounts.

The targeted maintenance consultant will establish contact with the equipment maintenance personnel and provide long-term technical support in subsequent maintenance.

Technical Support: Yandex