Infant cereals play an important role in the complementary feeding period. The aim of this study was to review existing research about the quantity, type, and degree of infant cereal processing, with a special focus on whole grain infant cereals. Accumulating evidence shows many benefits of whole grain consumption for human health. Likewise, consumers are frequently linking the term whole grains to healthiness and naturality, and sustainable food production becomes a more important aspect when choosing an infant cereal brand. Whole grain cereals should be consumed as early as possible, i.e., during infancy. However, there are several challenges that food manufacturers are facing that need to be addressed. Recommendations are needed for the intake of whole grain cereals for infants and young children, including product-labeling guidelines for whole grain foods targeting these age stages. Another challenge is minimizing the higher contaminant content in whole grains, as well as those formed during processing. Yet, the greatest challenge may be to drive consumers’ acceptance, including taste. The complementary feeding period is absolutely key in shaping the infant’s food preferences and habits; therefore, it is the appropriate stage in life at which to introduce whole grain cereals for the acceptance of whole grains across the entire lifespan.

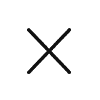

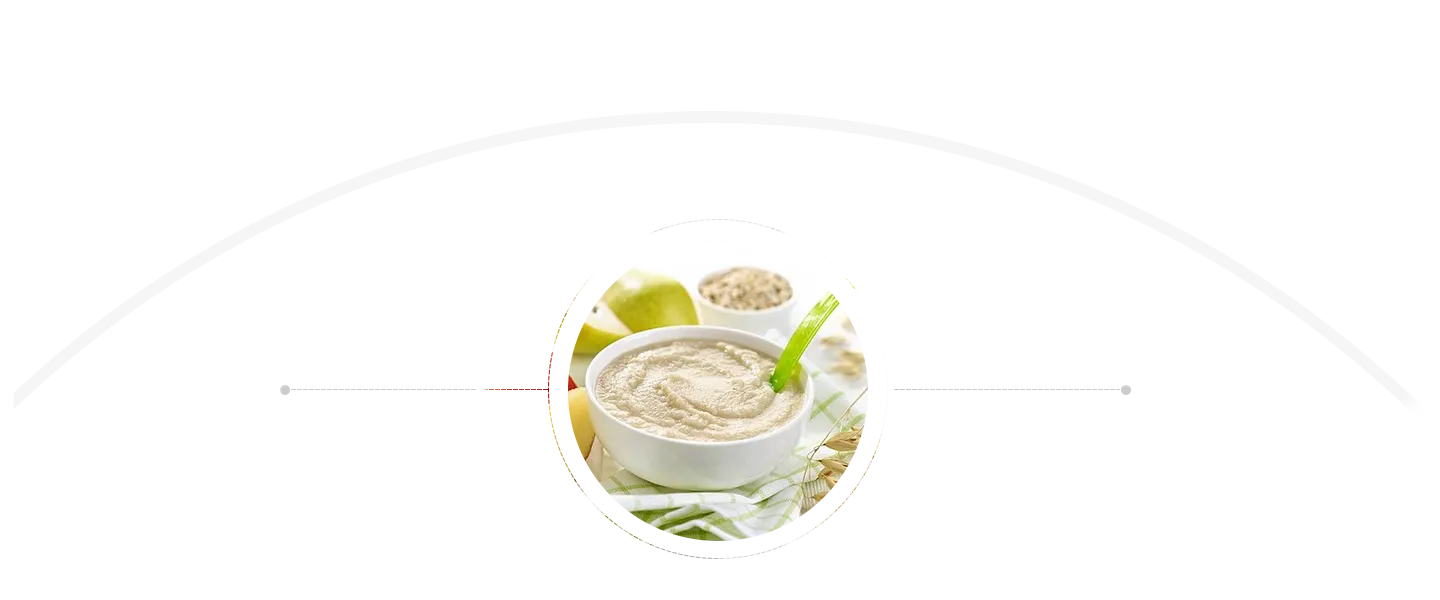

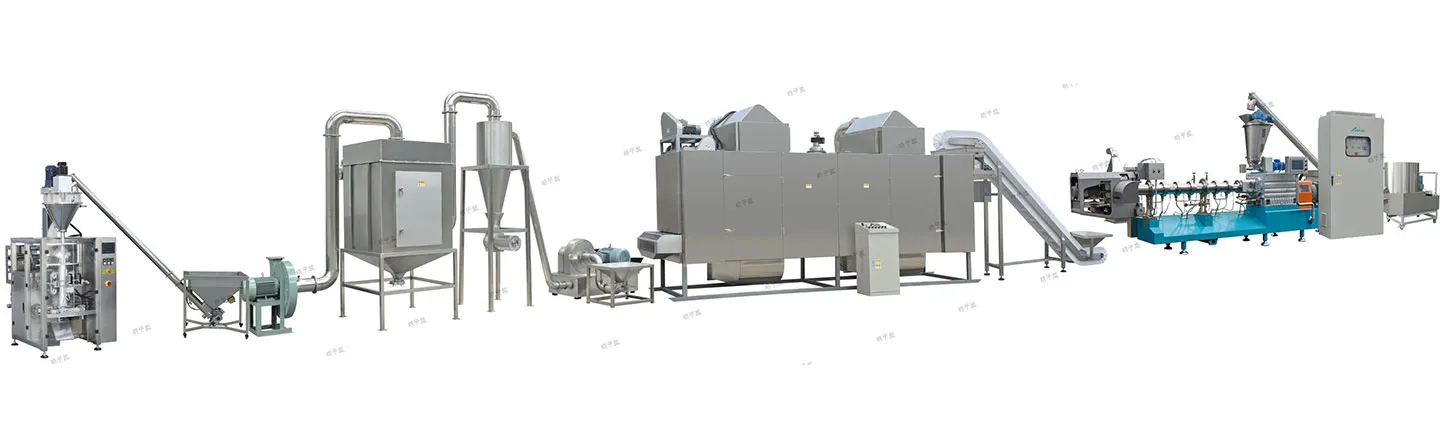

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Ribbon mixer consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer...

Ribbon mixer consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer...

Modified starch is the starch extracted from grains and vegetables which has been treated to improve its ability to keep the texture and structure of the food. We use modified starch in food products that need to be microwaved, freeze-dried, cooked at high temperatures (for example, a ready-made pizza, instant soup, sauces) or baked and fried so that the texture of such food does not change during the cooking process.

There are three different ways of modifying starch – it can be cooked or roasted (which is called physical modification), treated with enzymes (enzymatic modification) or with various chemicals (chemical modification). All modified starches are safe to use in the EU – they are independently tested by the European Food Safety Authority in order to guarantee their safety.

Arrow Machinery provide the turnkey solution for the modified starch production line by physical modification. Including the Flour mixing, Extrusion, Pre-drying, Flaking, Hot air roasting, Coating, Drying, Cooling, Packing system.

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Ribbon mixer consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer...

Ribbon mixer consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer...

Technical Support: Yandex