As the global continues to move toward natural, low-dust, and eco-friendly products, tapioca cat litter has emerged as a fast-growing category in the cat litter market. Made primarily from plant-based tapioca starch, this innovative litter solution is gaining popularity among pet owners and manufacturers alike.

This market shift is also accelerating demand for advanced cat litter production lines capable of processing natural starch-based materials with stable performance and high efficiency.

Tapioca cat litter is mainly produced from tapioca starch, which becomes elastic and semi-transparent after water addition and heat treatment. This characteristic allows the litter granules to achieve excellent water absorption and strong clumping performance.

Some formulations may include small amounts of baking soda or plant enzymes to enhance deodorization. These material properties place higher requirements on production equipment, particularly in terms of mixing uniformity, temperature control, granulation stability, and drying precision.Low-Dust and Low-Irritation Demand Boosts Equipment Innovation

One of the key advantages of tapioca cat litter is its minimal dust generation, making it suitable for cats with sensitive respiratory systems. To meet this market expectation, manufacturers increasingly require sealed conveying systems and optimized forming structures during production.

Modern cat litter production equipment is designed to reduce dust emissions during feeding, granulation, and drying processes, ensuring consistent product quality and a cleaner production environment.

Fast water absorption and firm clumping are critical selling points of tapioca cat litter. These properties are highly dependent on precise moisture control, controlled gelatinization, and stable particle density during production.

By optimizing processing parameters across mixing, forming, and drying stages, high-quality cat litter production lines can consistently deliver uniform granules with reduced breakage and minimal bottom sticking.

As a biodegradable, plant-based cat litter, tapioca litter aligns well with global sustainability regulations and environmental policies. This has driven manufacturers to invest in energy-efficient, environmentally responsible cat litter production equipment.

Modern production lines focus not only on output capacity, but also on reduced energy consumption, high raw material utilization, and long-term operational stability.

In practical applications, tapioca cat litter is often blended with tofu cat litter or bentonite cat litter to improve clumping strength or reduce sticking issues. This trend requires production equipment with strong formulation compatibility and flexible process adjustment capabilities.

Flexible cat litter production lines enable manufacturers to quickly respond to market changes and expand diversified product portfolios.

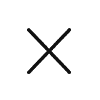

Shandong Arrow Machinery Co., Ltd. is a professional enterprise specializing in the research and development and manufacturing of production equipment for pet food and pet supplies. The company's products cover cat litter production lines, dry pet food production lines, wet pet food production lines, aquatic feed production lines, pet treats production line mixing systems, molding and drying equipment, etc., widely serving pet food and pet supply manufacturers worldwide.

With extensive industry experience, advanced manufacturing capabilities, and a strong focus on innovation, Shandong Arrow delivers efficient, stable, and customizable turnkey production solutions to pet product manufacturers worldwide.

Technical Support: Yandex