Laboratory Animal Feed Production Line Solution: Precise and Safe Production Solutions

This solution is designed specifically for the scientific research and pharmaceutical sectors, providing a high-precision, automated laboratory animal feed production line to ensure nutritional accuracy and sterility compliance.

Core Modules:

● Raw Material Processing: Crushing, screening, and an automatic weighing system precisely blend grains, proteins, vitamins, and more.

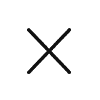

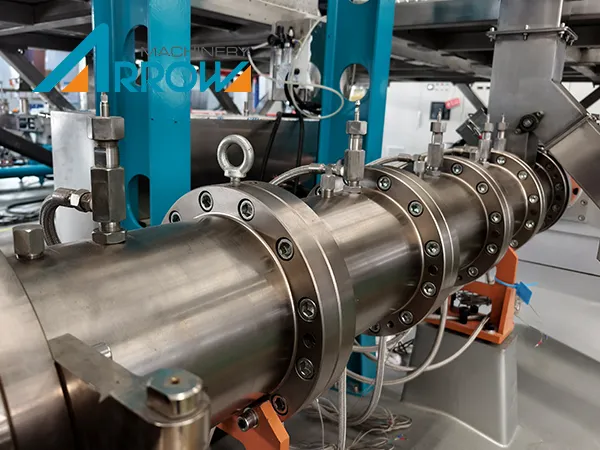

● Mixing and Granulation: A twin-shaft mixer + twin-screw extruder uniformly mixes and forms granules/powders.

● Sterilization and Cooling: High-temperature sterilization (steam/radiation) ensures sterility, while cooling equipment prevents nutrient loss.

● Packaging and Traceability: Vacuum/nitrogen-filled packaging, with a QR code system recording batch, ingredients, and sterilization parameters.

Technical Highlights:

●Precision Control: PLC system with real-time monitoring, error ≤ 0.5%, and consistent formulation.

●Sterility Assurance: GMP standards, total colony count ≤ 10 CFU/g, meeting SPF requirements. ●

Efficient and flexible: Capacity ranges from 200-600 kg/h, with a modular design suitable for a variety of feed species.

●Full traceability: Data traceability ensures compliance with GLP/GMP research regulations.

Process: Pretreatment → Mixing → Granulation → Sterilization → Cooling → Packaging → Quality Inspection.

Advantages:

●Ensures the reliability of experimental data;

●Automation reduces contamination risks and costs;

●Supports the compliance needs of research institutions and pharmaceutical companies.

Applicable to: Research institutes, pharmaceutical companies, and laboratory centers.

Services: Installation and commissioning, training, verification documentation, and lifelong maintenance.

Conclusion: Empowering research with precision and safety, promoting industry standardization.

Using corn, wheat, oats and other multiple grains as raw materials, it is matured and formed by a high-quality twin-screw extruder. The product is crispy and has high nutritional value, suitable for people of all ages.

Produces feeds that are tailored to the characteristics of laboratory animals

Easy mold replacement for quick change of product shape.

The production process does not change the product properties and maintains the raw material properties.

Small batch production can be realized to avoid waste.

Corn flakes, rice flakes, whole wheat flakes, breakfast cereals, gluten, instant cereals, crispy cereals, fruit cereals, custard stars, honey rings, high fiber whole wheat fiber, whole grains dietary fiber cereals

Technical Support: Yandex