Pet Snack Production Line Solution: Efficient and High-Quality Production Solutions

To meet the pet snack market's demand for both taste and nutrition, this solution provides an efficient and intelligent snack production line, achieving automated production and quality assurance.

Core Components:

● Raw Material Processing: Grinding and mixing equipment ensures uniform raw material distribution;

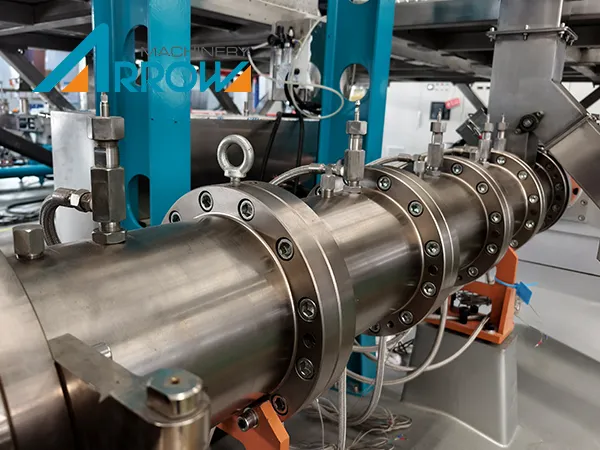

● Filling Forming: A twin-screw extruder combined with a precision injection system ensures a crispy outer layer and tightly integrated inner layers of sauces (meat, cheese, etc.);

● Post-Processing: Low-temperature baking and automated packaging (metering, sealing, and coding) support multiple packaging formats.

Technical Advantages:

● Intelligent: A PLC control system monitors parameters in real time, enabling flexible production and rapid switching between recipes and molds;

● Quality Assurance: HACCP-compliant equipment with full traceability to prevent contamination;

● Efficient and Environmentally Friendly: Automation reduces costs and increases efficiency, while energy-saving designs reduce energy consumption.

Production Process: Raw Material Pretreatment → Extrusion and Forming → Cooling and Forming → Seasoning and Coating → Packaging and Quality Inspection – fully automated. Benefits and Competitiveness:

● Differentiated Products: The sandwich structure enhances appeal;

● High-efficiency Production Capacity: 100-1000 kg/hour (customizable);

● Flexible Adaptability: Rapidly respond to market demand;

● Brand Premium: Technical support supports high-end positioning.

Applicable Scenario: Medium- to large-sized pet food companies, suitable for innovative product categories and high-end market expansion.

Service Support: Equipment installation, training, and long-term after-sales service are provided.

Using corn, wheat, oats and other multiple grains as raw materials, it is matured and formed by a high-quality twin-screw extruder. The product is crispy and has high nutritional value, suitable for people of all ages.

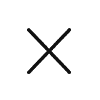

Extruder with large aspect ratio and good product maturation.

The equipment is manufactured according to European standards for high efficiency and durability.

The process flow is reasonably designed to ensure the quality of product production.

The core injection is even, the final product is full, the sealing is good, no leakage of core.

Corn flakes, rice flakes, whole wheat flakes, breakfast cereals, gluten, instant cereals, crispy cereals, fruit cereals, custard stars, honey rings, high fiber whole wheat fiber, whole grains dietary fiber cereals

Technical Support: Yandex